- Home

- Categories

- Roof

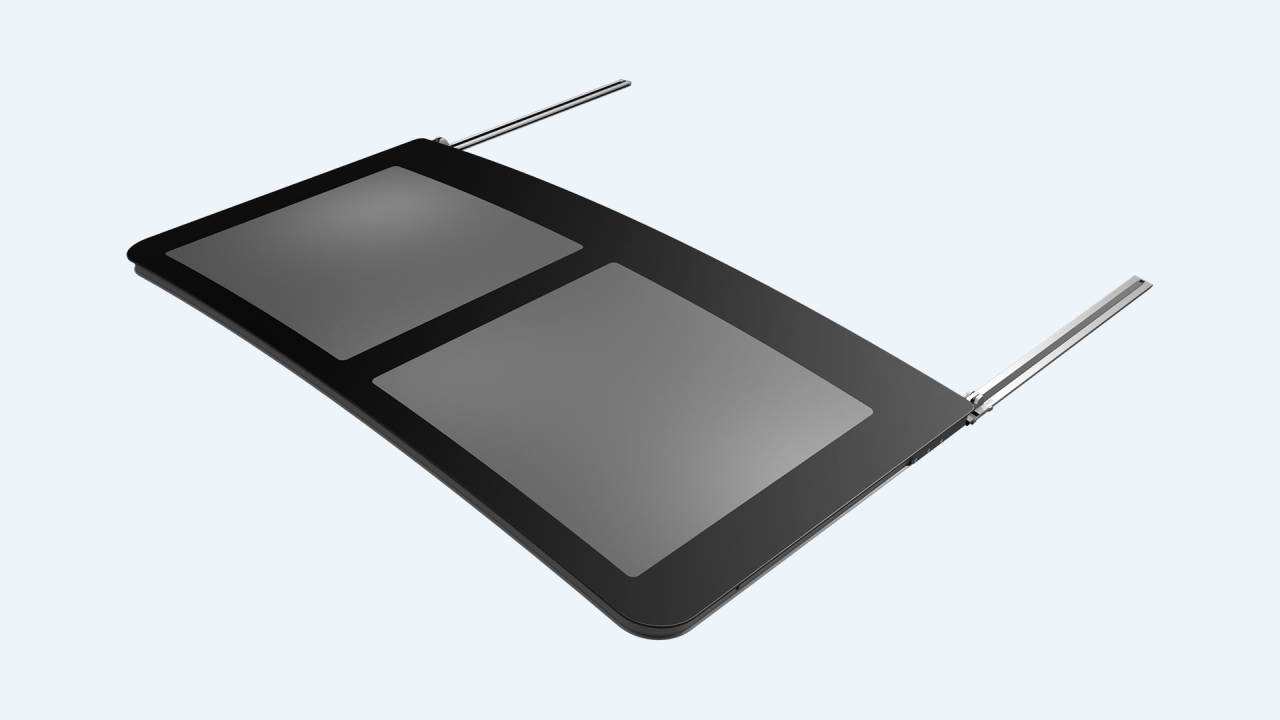

- 150-Series

Description

The surfaces are completely flattened and their double curvature contributes to the uniqueness of the design and will suit any yacht. The 150-series is delivered as an integrated system and the installation requires technical documentation with instructions and recommendations from the manufacturer or distributor.

Types

Glass/ fiberglass (GRP)/ sandwich construction

Dimensions

length (total length of the system approx. 4,000 mm)

width (total system width approx. 2,500 mm) / curvature

Technical description

- frame (made of stainless steel, laser cut and welded)

- sealant (internal sealant attached to the hard top thus achieving 100% water tightness)

- tilting and sliding mechanism (attached to part of the frame, brackets for fastening to the panel included)

- power system 24 V DC motor (attached to part of the frame and connected to the mechanism)

- panel (front and back)

- manual start of the roof with a special key (for example in case of power failure)

Characteristics

- complete roof construction

- waterproof sealing

- a diverse selection of board materials

- large dimensions of the roof construction and open part

- sliding panel with tilt on the front and back

Additional info

- Complete watertightness – This roof is unique on the market due to its proven water tightness. Rainwater infiltration is not possible even during ventilation when the roof panel is in a sloping position.

- Roof installation position – Possible installation in area 2 or 3, depending on the size of the roof.

- The best roof dimension – The roof system is available in different dimensions from 1.5 m long and 1.8 m wide and can be adjusted with transom and color, all to fit perfectly into the design of your boat. In terms of style and functionality, it is best to choose the largest possible unit.

- Roof control – The opening can be operated while the boat is in motion or at rest.

- Hull thickness for roof installation – The roof can be installed on top or aligned with the surface regardless of the hull thickness and the installation of the system is similar to that of a standard opening.

- Maintenance – Anodized or coated aluminum is an extremely durable material and does not require special maintenance but it needs to be cleaned regularly. Particular attention should be paid to the outer rails to ensure smooth movement, without jamming, and this includes the removal of dust and cluster. We recommend occasionally rinsing the roof with lukewarm water if necessary, adding a small amount of liquid soap which needs to be rinsed thoroughly.

- Cleaning products to avoid – Do not use alkaline products that contain caustic soda, so be careful with glass cleaners that can also be alkaline and therefore corrosive. Do not use acidic products such as hydrochloric acid or products with fluorescent substances. Do not use rough brushes, steel wool, scrubbing products or sandpaper for cleaning.

- Thickness – We offer high quality acrylic glass panes 15 mm thick or glass of different thicknesses

- Radius – Max. length (L1), max. width (W1), flanging radius (R1), min. roof radius (R2), roof with transom 1,100 (L1) 1,100 (W1) 80 (R1) 10,000 (R2), roof with transom in opening direction 1,100 (L1), 1,800 (W1), 80 (R1), 10,000 ), roof with transom transverse to the opening direction 1,500 (L1), 1,100 (W1), 80 (R1), 10,000 (R2). All dimensions are expressed in mm and the minimum roof radius is 10,000 mm.

- Finish – There is a choice between acrylic, glass and solid aluminum panes. Gray, bronze and green colors and a transparent window are available. Then, anodized or RAL coated aluminum available in all colors.

- Flanging radius – The roof has a flanging radius of 80 mm.

Similar products

Check out other products from this category